The Best Strategy To Use For Roar Solutions

( Area 0, 1, or 2). This variant will certainly also influence the resourcing demands for job prep work. As soon as Lots are defined, you can create tasting strategies based on the sample size of each Great deal, which refers to the variety of arbitrary tools things to be inspected. To identify the needed sample dimension, 2 facets require to be examined: the dimension of the Whole lot and the group of inspection, which indicates the level of effort that should be applied( decreased, typical, or enhanced )to the evaluation of the Whole lot. By integrating the group of assessment with the Lot size, you can then develop the ideal denial requirements for an example, meaning the allowed variety of defective things located within that example. For more details on this procedure, please refer to the Power Institute Guidelines. The IEC 60079 standard advises that the optimum period between inspections should not go beyond 3 years. EEHA examinations will certainly also be conducted outside of RBI projects as part of scheduled upkeep and devices overhauls or repair work. These inspections can be attributed towards the RBI sample dimensions within the impacted Great deals. EEHA inspections are carried out to determine faults in electric equipment. A heavy scoring system is vital, as a solitary tool might have several mistakes, each with varying levels of ignition danger. If the mixed score of both evaluations is much less than twice the mistake score, the Whole lot is deemed appropriate. If the Lot is still considered unacceptable, it should undertake a full evaluation or validation, which might activate more stringent evaluation methods. Accepted Great deal: The reasons for any type of mistakes are recognized. If an usual failure mode is discovered, additional equipment might call for maintenance. Faults are identified by extent( Security, Stability, Housekeeping ), ensuring that urgent concerns are analyzed and addressed immediately to mitigate any effect on safety and security or operations. The EEHA database need to track and tape the lifecycle of mistakes in addition to the rehabilitative actions taken. Carrying out a robust Risk-Based Evaluation( RBI )method is crucial for guaranteeing conformity and safety in managing Electrical Equipment in Hazardous Areas( EEHA). Automated Fault Scoring and Lifecycle Management: Effortlessly handle mistakes and track their lifecycle to improve evaluation precision. The intro of this assistance for risk-based evaluation even more enhances Inspectivity's setting as a best-in-class service for governing compliance, as well as for any kind of asset-centric inspection use case. If you are interested in finding out more, we invite you to request a demo and uncover just how our option can change your EEHA administration procedures.

With over 10 years of mixed Ex lover experience (IECEx/ATEX, EEHA), Saipex started to promote the value of proficiency of all employees associated with the Hazardous Location field in 2019. In 2021, our collaboration with IndEx and Technology Ability International (TSI) marked a landmark in the Saipex road to proceed Ex renovation.

Roar Solutions - Questions

In terms of explosive danger, a hazardous area is a setting in which an explosive atmosphere exists (or may be expected to be present) in quantities that need special preventative measures for the building and construction, installation and use equipment. In this short article we check out the difficulties faced in the work environment, the danger control procedures, and the required proficiencies to work safely.

These materials can, in certain problems, create explosive environments and these can have significant and terrible repercussions. Many of us are acquainted with the fire triangle eliminate any type of one of the 3 components and the fire can not happen, yet what does this mean in the context recommended you read of hazardous areas?

This is after that verified with assessment and screening and is protected throughout the life of the setup by utilizing the correct maintenance strategies, supplemented by periodic examination. When all these measures are taken, they must additionally be documented. The confirmation file includes details such as the dangerous location category drawing, manufacturers' paperwork, tools certification, layout drawings and computations, assessment documents, and records of an individual's expertise and proceeding professional advancement (CPD), such as using ECA's eCOMS software.

Roar Solutions Things To Know Before You Buy

It is necessary that pupils recognize and have an extensive expertise as to exactly what comprises a hazardous area. The pupil should also understand why training is necessary before trying to handle work or specifying tools into an unsafe location. These areas are also understood as categorized locations and are defined as areas which have a high possibility of an explosion due to the feasible existence of flammable gases, vapors, dusts and so on.

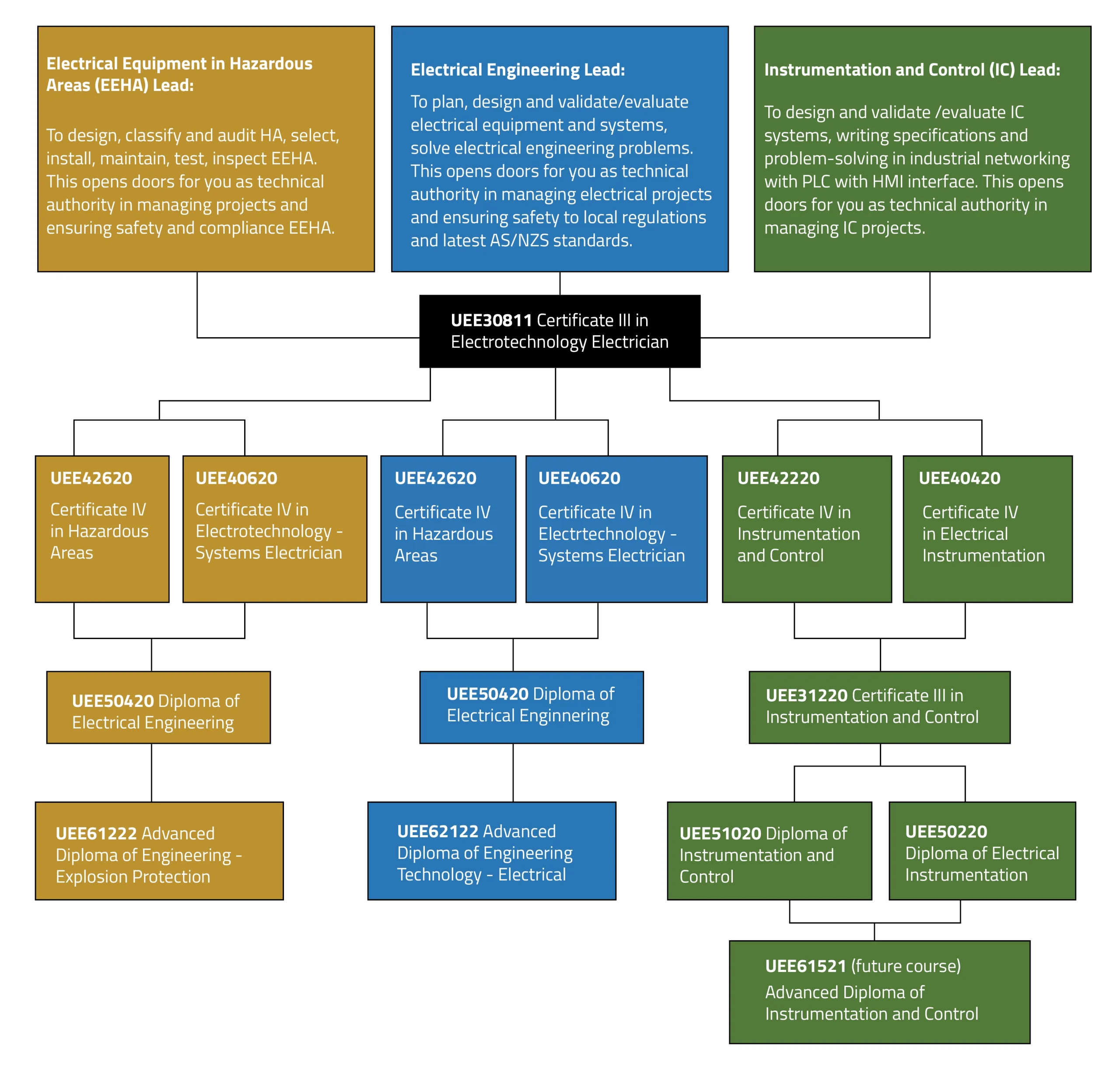

Industries that have unsafe locations are currently requiring that electric workers that are specifying or operating in these locations need to have a dangerous area certification that deems them skilled. Jobs in these sectors are really satisfying so you require to be prepared. To meet this need for the sector, country wide identified training in Certification IV in Unsafe location Electrical and EEHA training on the development of competent experts.

Roar Solutions for Beginners

Technology Skills Australia is a Registered Training Organization offering you with the most affordable and quickest method in acquiring your certification - Roar Solutions. Our trainers are market qualified and have a number of years of process experience. Our programs have helped hundreds of individuals from company managers to everyday workers in obtaining a strong hang on this not so complicated yet high threat training

The training likewise consists of recognizing the harmful areas, resources of surge and the homes of dangerous materials in addition to the duties and features of all celebrations, policies, systems, standards and technique codes linked to harmful areas. We give instrumentation and harmful area services that remain in conformity to latest AS/NZS and international sector requirements.

Comments on “9 Simple Techniques For Roar Solutions”